Model DST-6® Street Sweeper

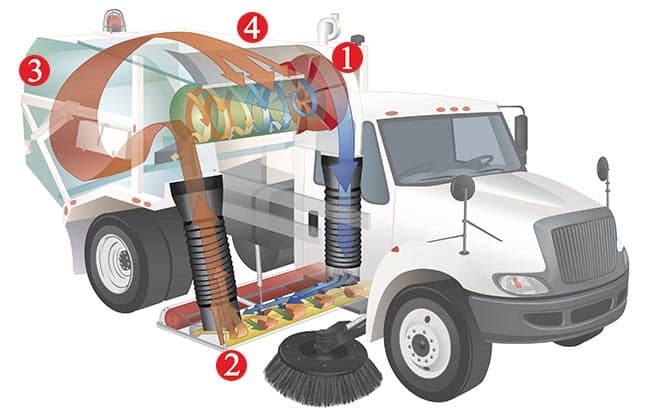

The TYMCO Model DST-6, the industry’s first full-sized dustless sweeper. The DST-6 removes dirt, dust and debris from the sweeping surface, and uses filters that have a Minimum Efficiency Reporting Value (MERV) 16 Rating, meaning they are able to capture a minimum of 95% of 0.30 micron and larger size particles, far exceeding PM10 requirements.

TYMCO's patented filtration system enables the DST-6 to be equally efficient in wet or dry conditions, so you don't have to avoid puddles and leave debris behind. Our DST System when coupled with our Regenerative Air System produces the most technologically advanced street sweeper available today.

The DST-6 sets the performance standards for particulate matter removal in the U.S. and Canada. Mounted on a highly maneuverable cabover "standard truck chassis," the DST-6 can travel to the job site at legal speed limits and then perform the dustless cleaning required in industrial and municipal applications.

The dustless features are engineered to allow the sweeper to perform in all types of weather conditions with no operator adjustments required.

TYMCO Sweeper Design

TYMCO Sweepers are designed in way that truly reflects the culture at TYMCO. When our engineers approach a challenge or a need on the sweeper, they work to develop straightforward solutions. For example, all TYMCO Sweepers use True Regenerative Air. This design delivers the simplest approach as well as the highest performance with the lowest downtime as compared to other sweeper technologies.

- True Regenerative Air

- Smart Gutter Broom

- Operator Friendly Design

- Easy Access to Components

- High Productivity

- Low Maintenance

More About TYMCO Sweeper Design

Features

Broom Assist Pick-Up Head

The TYMCO Model DST-6 pick-up head has a width of 87 inches and is equipped with a broom in the pick-up head for applications where a broom is desired. The fast rotation of the broom loosens packed-on debris and projects it into the Regenerative Air stream for effective cleaning.

With in-cab controls that allow broom-assisted sweeping only when needed, the operator can lift the broom out of service for regular use of the powerful Regenerative Air system.

Hopper

The Model DST-6 hopper is over 7.3 cubic yards in size with a useable capacity of over 6 cubic yards. Stationary hopper dumping system designed for safe, simple dumping and low maintenance.

This eliminates dumping cylinders and hoist, hydraulic controlled door latch assemblies, additional hydraulic door opening cylinders, grease zerks, and safety concerns such as pinch points and overhead clearance issues.

Gutter Broom

Gets debris out of the curb/gutter with large 43" diameter gutter brooms with in-cab control. Tilt gutter broom allows you to reach down into the deepest gutters.

TYMCO's large 43" gutter broom design has a pressure-sensing sequence valve to automatically determine the digging pressure needed for different debris; therefore, customers get maximum broom bristle life and cleaning performance.

From inside the cab, the operator can control the speed of the gutter brooms. This allows the operator to match the speed of the truck while sweeping to lessen the least amount of dust being kicked up.

Dust Control

TYMCO incorporates a high efficiency multi-pass cylindrical centrifugal dust separator for maximum particulate separation and sweeping performance. Designed for easy clean out and maintenance.

On board 220 gallons of water for dust control around the gutter brooms and inside the hopper. For below freezing conditions, the sweeper will continue sweeping dustless without using water.

DST System

The small amount of air that is diverted from the system to achieve the dustless effect is filtered through TYMCO’s patented DST system. The DST System will filter the diverted air through a pre-cleaner and cartridge filters. These filters have been determined through independent laboratory testing using the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) 52.2 testing standards to have a Minimum Efficiency Reporting Value (MERV) 16 Rating, meaning they are able to capture a minimum of 95% of 0.30 micron and larger size particles. That is 1/200 of the diameter of a human hair! The best part is that both the pre-cleaner and cartridge filters are washable, ensuring long service life.

Power Unit

The Model DST-6 sweeper is powered by a 99 horsepower John Deere auxiliary engine. This engine powers all hydraulic functions through a gear driven pump and directly belt drives the blower wheel.

Blower Wheel

We use a natural rubber coated aluminum blower wheel which we have found ti be abrasion resistant as well as reduces fuel consumption because of its lightweight design.

Rear View Camera

Cities, streets, and roads are full of cars, maintenance equipment, signs, light poles, trees and many other objects that need to be seen when backing up. The rear view back-up camera with in-cab display allows the operator to view the area behind the Model DST-6 while backing up providing additional safety and peace-of-mind to both Model DST-6 operators and owners. Additional cameras are also available to view the pick-up head and gutter brooms.

Truck Types

Cabover

Peterbilt 220

Conventional

International MV607 or Freightliner M2

Options

Drop Down Gutter Brooms

Allows for the gutter brooms to "drop down" in front of the pick-up head so the metal bristles can scrub up extremely packed on material. Also allows very tight sweeping of curb lines to minimize amount of dust being kicked up before it is swept by the pick-up head.

Stainless Steel Hopper and Dust Box

For maximum corrosion and salt spray resistance all interior hopper body sheet surfaces to be fabricated with low carbon, high chrome stainless steel.

The hopper weldment, hopper door, skimmer hood, hopper screen and dust box assemblies are included in these options. Dust separator inlet scroll and door are not stainless steel. Stainless steel bolt-on blower housing, and dust separator are also available

Pick-Up Head Curtain Lifter

Hydraulic actuated and retractable roller assembly that provides the pick-up head with the ability to sweep large volume of light debris. Electronically controlled in cab.

Street Sweeping & The Environment

The Model DST-6 has several environmental benefits, features, and options including:

- Doing More With Less

- Water Efficiency

- South Coast AQMD Rule 1186 Certification

- ETV Verified for PM10 and PM2.5 Efficiency

Photo Gallery

Video Gallery

Model DST-6® Regenerative Air Sweeper®

Diesel Auxiliary Engine

Download PDFSweeper Auxiliary Engine

- Engine - John Deere 4045 turbo FT4, 4 cyl.

- Displacement - 275 in3 (4.5 L)

- Power - 99 HP @ 2200 RPM (74 kW)

- Net torque - 315 lb-ft @ 1600 RPM (427 Nm)

- Air cleaner - Heavy duty, w/pre-cleaner, scavenge vacuum hose, and in-cab air restriction indicator w/gauge.

- Remote oil filter - Spin on, full flow

- Diesel auxiliary engine fuel tank shared with cabover chassis, and independent from conventional cab chassis fuel tank.

- Aux. engine fuel tank capacity - 51 gal (193 L)

-

DEF tank - Dedicated

- Capacity (volumetric) - 5.4 gal (20.6 L)

- Capacity (useable) - 3.8 gal (14.4 L)

- Auxiliary engine protection system

- Fuel/water separator with WIF sensor

- Fuel filters - 10 μm primary, 2 μm secondary

- Open crankcase ventilation (OCV) filter

Blower, Rubber Coated

- Aluminum alloy, high volume, open face turbine

- Bearings - (2) sealed lifetime lube, anti-friction

- Bolt-on blower housing – Steel w/abrasion resistant, replaceable liner

- Drive - Heavy duty power band

Dust Separator, Rubber Lined, High Capacity

- Type - Cyclonic, multipass, centrifugal separation

- Size - 20 x 61 in cylindrical area (51 x 155 cm)

- Located adjacent to blower within hopper

- Particulate removal achieved through 61 in (155 cm) skimmer slot into skimmer hood

- Separator door opened from hopper exterior

- Abrasion resistant housing w/replaceable wear resistant liner

Hopper

- Capacity (volumetric) - 7.3 yd3 (5.6 m3)

- Capacity (useable) - 6 yd3 (4.6 m3)

- Construction - Welded steel plate with integral stiffeners

- Floor angle - 22°

- Dump door opening - 84 x 44 in (213 x 112 cm)

- Dump method - Hydraulic with raker bar

- Dump direction – Rear

- Dumping height - 36 in (91.5 cm)

- Inspection doors – (1) Each side of hopper, 9.75 x 29 in (25 x 73.5 cm)

- Abrasion protection package

- Hopper deluge system

Broom Assist Pick-Up Head (BAH®)

- Type - Dual chamber with broom assist

- Width - 87 in (221 cm)

- Pick-up head area - 3567 in2 (2.3 m2)

- Broom - 12 x 79 in enclosed in rear of pick-up head

- Suspension - (4) springs, (2) drag links

- Suction hose diameter - 14 in (35.5 cm)

- Pressure hose diameter - 14 in (35.5 cm)

- Skids - DUO SKID®, long-life carbide

- Pick-up head deluge

- Reverse pick-up head system

Gutter Broom, Twin, Patented

- Includes LED floodlights and parabolic mirrors

- Drive - Variable speed non-reversible hydraulic motor

- Adjustment - Adjustable for down pressure, pattern and wear

- Down pressure - Automatic

- Flexibility - Integral anti-damage "swing away" relief valve

- Broom - 43 in dia. (109 cm) steel wire, vertical digger, tilt, variable speed

- Hydraulic tilt - Adjust for curb depth

- Floodlights – (2) LED

- Parabolic mirrors – (2) 10.5 in (26.67 cm) dia.

Hydraulic System

- Operates gutter broom(s), dump and pick-up head

- Drive - Gear driven from auxiliary engine

- Flow rate - 8 GPM (30.3 LPM)

- Reservoir - 25 gal (94.6 L) with 80 mesh suction strainer, sight/temperature gauge

- Cooler - Air to oil, integral with auxiliary engine heat exchanger

- Return filter - 3 μm in-line

- Vent Filter - 10 μm spin-on

- Hydraulic oil – Extended life 10W ISO 46

- Hydraulic temperature shutdown system w/temperature gauge in cab

- Auxiliary hydraulic system

Dust Control System

- Water spray nozzles for dust suppression

- Pump - electric diaphragm

- Reservoirs - Polyethylene 220 gal (833 L) total

- Filter - 80 mesh in-line

- Low water shut-off - Safety shut-off with audible and visual indicator in cab

-

Spray nozzles:

- Gutter brooms (each) - 3

- Hopper (inside) - 1

- High output water system

- Hydrant fill hose w/storage area - 20 ft (6 m)

Dustless Filtration System

- An external mounted modular filtration system with automatic BlueLogic® control adjustment

- Capacity (volumetric) - 14 ft3 (0.40 m3)

- Filters - (4) MERV 16 Rated

- Particulate removal efficiency ≥ 95% of 0.3 µm

- Long life filters, not effected by wet sweeping conditions.

- Filters cleaned by intermittent air pulse

- Air compressor - Belt driven, liquid cooled, engine lubricated

- Compression rate - 13.2 CFM (0.37 m3/minute) @1200 RPM

- Shop air connection for air pulse system

- Dust box deluge washout system

Control System

-

BlueLogic® Control System

Multiplexed electrical system includes hardware and TYMCO designed software that integrates the in-cab controls to the auxiliary engine and all sweeper functions; as well as provides intelligent safety features and on-board diagnostics (OBD) for the auxiliary engine and sweeper through the BlueLogic display. Specific to DST models, BlueLogic also monitors and automatically controls the adjustments for the DST system, requiring no operator adjustments. -

BlueLogic Display

Pedestal mounted touchscreen display provides sweeper and auxiliary engine data and includes hour meters (trip and total) for the auxiliary engine, gutter brooms, pick-up head, blower, water pump, BAH broom, and DST filters; sweeper odometer (records curb miles swept and sweeping hours), service reminders, custom reminders, overspeed warning, low water audible alarm, dust control system winterization guide, and OBD. -

Interior Components

BlueLogic display, auxiliary fuse panel, illuminated control switches: pick-up head, gutter brooms, auxiliary engine RPM, DST mode, purge system, variable speed gutter brooms, dust control water system nozzles, safety lights -

Exterior Components

Dump switch, BlueLogic Control Modules (BCMs)

Safety/Warning Devices

- Alternating LED rear flashers (2)

- Rear view camera system

- Back-up alarm

- SAE Class 1/California Title 13 amber beacon light with limb guard - LED

Optional Equipment

- AOD water pump w/washdown hose/gun

- Additional camera views - pick-up head, left gutter broom, right gutter broom

- Auto Sweep Interrupt (ASI)

- Auxiliary hand hose 8 in dia. (20 cm)

- Auxiliary hand hose hydraulic boom assist

- Gutter broom drop-down

- Hi/Low pressure washdown system

- Hopper drain system

- Magnet: Light, standard, or heavy duty

- Pick-up head curtain lifter

- Pick-up head deluge (BAH®)

- Shop air purge, dust control system

-

Stainless steel (non-magnetic) options:

-

Hopper & dust box:

-Hoper weldment

-Dump door

-Inspection doors

-Raker plate

-High capacity dust separator

-Hopper screen

-Dust box - Blower housing

- Hopper drain

- Dust box

-

Hopper & dust box:

- Paint color (other than TYMCO standard white)

Special options are available for your individual requirements. Contact your local dealer or TYMCO.

Chassis Available

- Peterbilt 220

- International MV607

- Freightliner M2-106

Updated: 06/06/2024